Swiss Pagani Works’ multi-disciplinary team supports you to engineer and manufacture your products and components successfully and sustainably. With our unique holistic approach, we make sure, everything comes together: We streamline processes, reduce risks and optimize costs, all customized to your specific requirements.

Customers

Our clients and their projects come from a variety of industries and backgrounds. We have learned to understand their needs and expectations.

Industrial components

At Pagani Works we engineer, mold and assemble plastic components for all industries and applications. And we also know how to combine metal parts and plastic components.

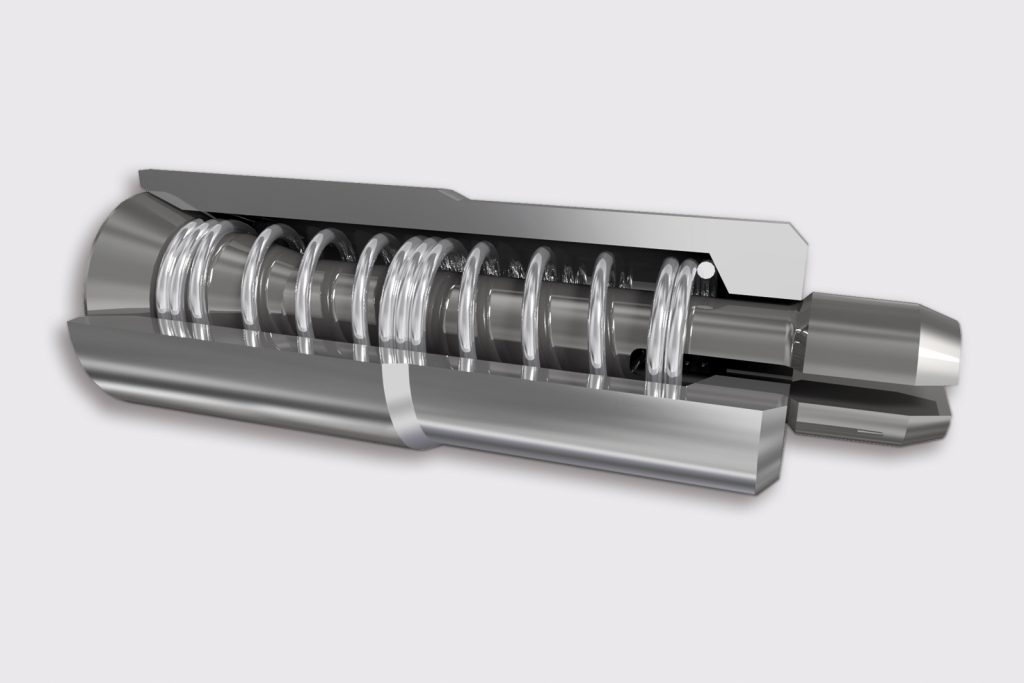

Spring Vents

Using state-of-the-art Pagani Works’ spring vent technology offers a whole series of benefits. Disassemblable spring vents of stainless steel prevent rubber overflow in the manufacturing of tyres meaning a substantial annual saving in rubber consumption and a sustainable reduction of unrecyclable vulcanized rubber waste.

Automotive

We know what it takes to make good molds. For example, for headlights, rearview mirrors, air vents, under door elements, tanks and logos (bi-tri-quad injection).

Toys

Pagani Works offers a comprehensive feasibility analysis according to EN 71 standards and a customized production to meet your cost and quality targets.

Childcare

We design, develop, and build molds for baby bathtubs, bottles, pacifiers and soothers in silicone, as well as for cribs and car seats.

Furniture

Pagani Works creates molds for components and small parts and studies and analyzes design requirements for ergonomic chairs.

Medical

We have a proven record in the study and analysis of design requirements for medical devices and in the building of molds for casings and structures (semi-expanded).

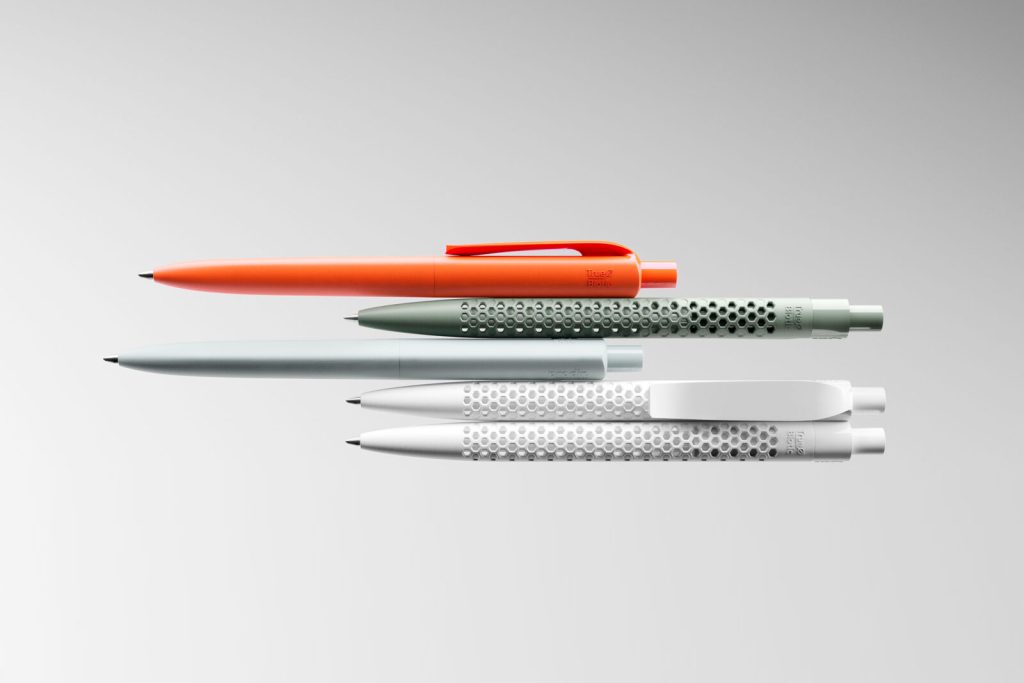

Cosmetics

Pagani Works is experienced in the study, analysis and making of molds for eyeliners and automatic pencils.

Services

Drawing in our experience in innovative materials and manufacturing and activating our extensive global network, Pagani Works develops customized solutions to bring your concept to mass production.

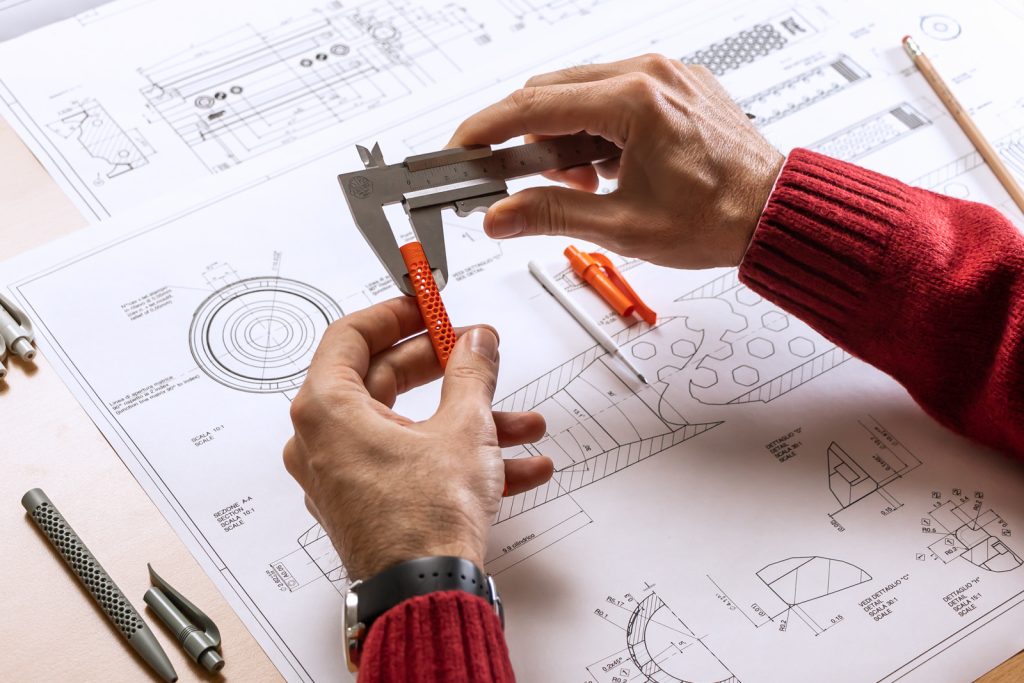

Engineering

Services include feasibility analysis, 3D solid modeling of product (CREO 7 and Inventor 2022), FEM analysis, renderings, mock-ups and functional prototypes, 3D solid modeling for molds and dimensional control drawings for production.

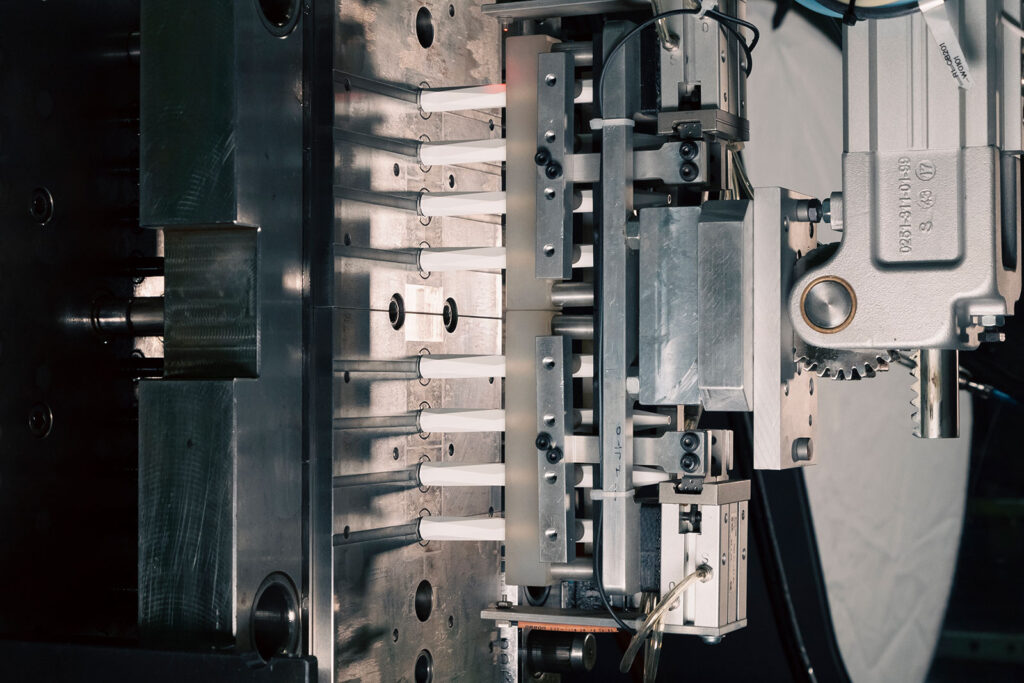

Mold definition & design

Services include analysis of mold structure and type (pilot, pre-series, or production) and realization of executive project with definition of construction tolerances.

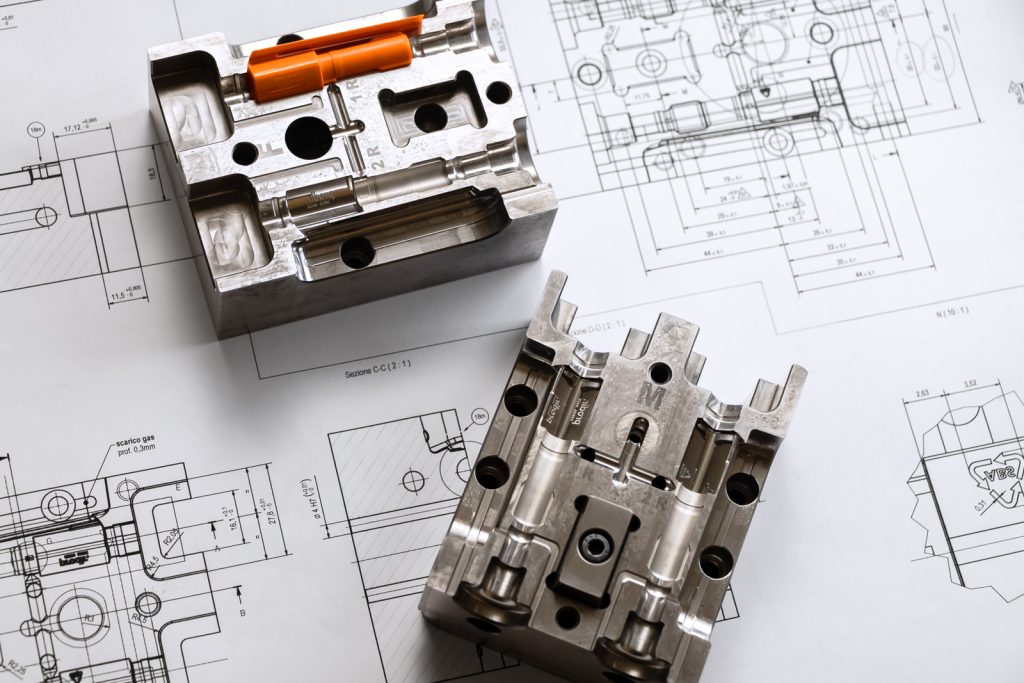

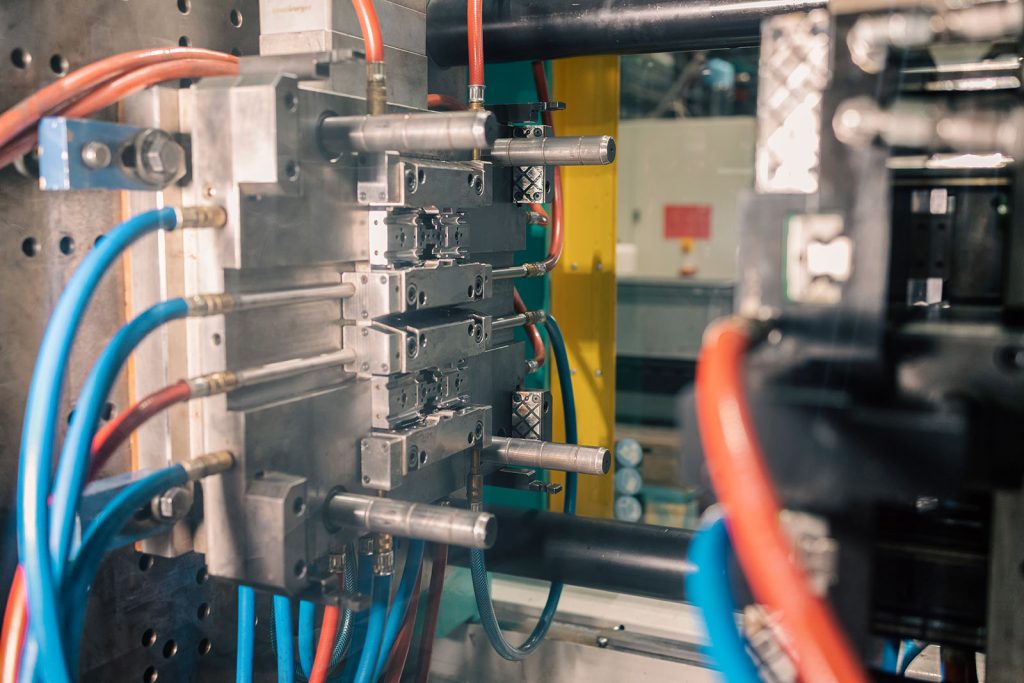

Mold construction

Services include realization of molds using CNC technologies, mold testing and functional checks, control of molded component (analysis and report by Zeiss measuring device), on request refinement for modifications and final tests for customer validation.

Production (plastics)

Services include assistance to production start up at customer’s premises or pilot production and validation of production by customer at Pagani Works.

Production (metal parts)

Services include feasibility analysis, 3D solid modeling, manufacturing of samples, realization of 2D drawings, dimensional control with Zeiss measuring device, production on CNC machining centers, EDM machine, CNC lathes and grinders as well as PM and Mikron Multistar machines. Own production includes ISO9001 certified high precision spheres (dimensions < 2”).

Sustainability, materials, packaging

Pagani Works is a pioneer in the use of sustainable materials like PHA, PHB, PLA, recycled and regenerated ABS, PP and PET. Our services include a feasibility analysis with a holistic approach to a green supply chain. We have a proven record in engineering products and designing processes with special consideration for the environmental impact of a product during its whole lifecycle (eco-design). On request we deliver an analysis and proposal for packaging.